You're losing money on every job And you don't Even Know It

You know your margins are tight. What you might not know is why.It's not your crew. It's not your estimator. It's simpler than that: the material costs in your pricing are wrong. They're outdated. Sometimes by months. And every quote you send is bleeding profit you'll never see again.Most HVAC contractors are leaving tens of thousands on the table each year. Not because they're bad at business — because material costs change faster than you're updating them.

Here's What's Actually Happening

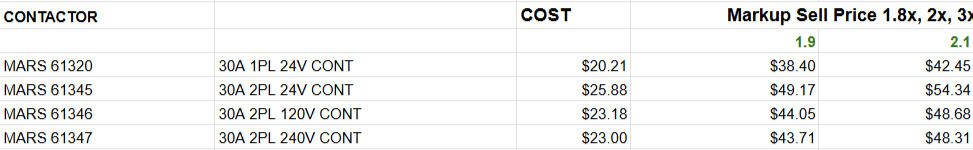

You bought a contactor last year for $20. You marked it up and billed it $50. Profit: $30.Today, that same 30A 2 Pole 24 Volt Contactor costs $25. If you updated your pricing, you'd bill $62.50 at the same 2.5× markup. Profit: $37.50.But you're still billing $50 because nobody updated the cost baseline.You should be profiting $37.50. Instead you're profiting $25. That's $12.50 missing per unit.Multiply that across every part, every job, every month—and suddenly you're wondering why the bank account isn't keeping up.This is why your materials expense keeps creeping up as a percentage of revenue. Not because you're buying more. Because what you're buying costs more, and your pricing hasn't caught up.

TWO WAYS YOU END UP WITH THE SAME PROBLEM

Path #1: You Notice It Climbing Year Over YearMaterials expense was 31% two years ago. Last year it was 34%. This year it's 36%.You're updating costs quarterly at best. Meanwhile, vendor prices shift monthly, sometimes weekly. That gap bleeds margin on every job—the contactor, the copper fittings, the capacitor. Death by a thousand small gaps.What this costs you:Most contractors don't notice until year-end P&L shows materials expense climbed several points. By then, you've left tens of thousands on the table.

Path #2: Higher Material Expense Than Industry StandardYou look at your P&L and see materials eating 38% of revenue. You talk to peers or your accountant and learn it should be closer to 33%.That 5 point gap on 1MM? That's $50,000 in missing profit.Whether it crept up over time or was always high, the result is the same: you're keeping less profit per job than you should.

Either Way, We Fix It The Same Way:Your materials expense drops back to healthy levels. We update your cost baseline to current vendor pricing, apply markups you need to hit target margins, then monitor ongoing so it never drifts again.

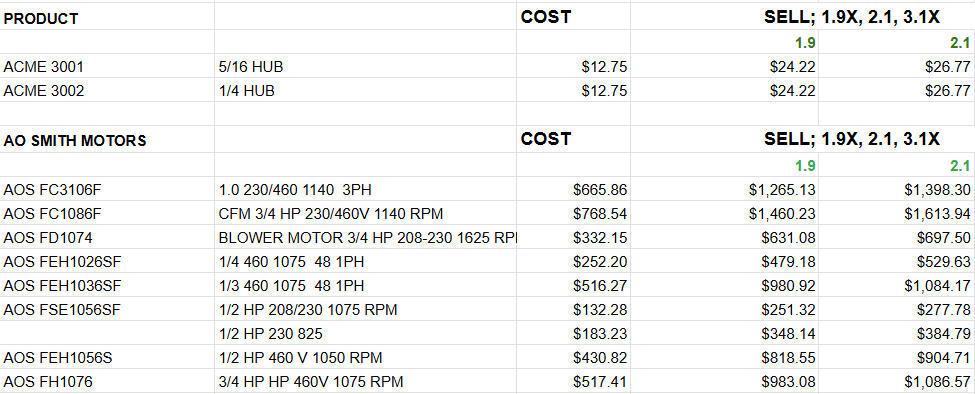

See exactly what you're losing

How we get your profit back

We're not selling you software. We're not plugging in AI. This is a person sitting down with your materials list and fixing it - then keeping it fixed so you stop losing money.Here's exactly what happens:We pull fresh costs directly from your vendor websites. We update your baseline SKU list with current pricing in a spreadsheet built around how you markup each part type. You get an always-current cost sheet that reflects today's reality—not March's numbers in November. From there, you feed it into your ERP, estimating software, or use the spreadsheet itself for quoting.Recover tens of thousands in year one.That's not revenue. That's pure profit—money that was always yours, just leaking away unnoticed. We plug the leak. You keep the cash.

Purpose-Built for HVAC/R Companies Who Live on Tight Margins

You know the problem. Your materials expense is crushing you, but you don't have bandwidth to chase vendor pricing as often as you should. That's what I do.

Here's What Happens Next

Book a 15-Minute Call

We'll discuss your financials, confirm how much you're bleeding, walk through how our service works and what we do/don't do. No sales pitch—just an honest conversation about whether this makes sense for your business.

Questions you probably have

How does the service work?

First, we learn your pricing strategy—whether you pass through savings or hold price when costs drop, and how you structure markups across different vendor tiers. Then we build a clean baseline of your key SKUs (filters, driers, motors, belts, contactors, etc.) with a markup table that reflects your approach. From there, we continuously update that baseline with current vendor costs so every bid, quote, and invoice reflects your true strategy—no margin erosion, no hidden leaks.Will this disrupt our current workflow?

Zero disruption. You keep quoting as usual while I update costs behind the scenes. We establish your baseline in about 30 days, and recovery begins with the very next bid. Your team won't need to change how they work.Don't our vendors already give us fair pricing?

Fair pricing is great, but even fair prices go stale when costs shift. The issue isn't unfair vendors—it's the lag between when costs change and when your pricing reflects it. I eliminate that lag so updates hit your jobs instantly.Our ERP system handles pricing updates. Why would we need this?

ERPs are powerful calculators that reflect whatever data you feed them. If vendor cost data is months old, your ERP will scale outdated numbers beautifully.What if our vendors push back on this?

I don't negotiate pricing or interfere with your vendor relationships. I pull current costs directly from your vendor websites and build you an updated baseline so you're quoting based on reality, not outdated information.How do I know your numbers are accurate?

They're not my numbers—they're your vendors' numbers, blended and kept current. We can prove accuracy side-by-side with your most recent vendor files. You'll see exactly where the data comes from and how it's applied.

EVERY DAY YOU WAIT IS More money WALKING OUT THE DOOR

Your team is putting an estimate together right now. What costs are they using? Last month's? Last quarter's?That job just cost you money before you even won it.